In the “Wastewater epidemiological surveillance in Vietnam” research project, instead of ordering a wastewater sampler from the US for $4,000 plus shipping to Vietnam, with total costs of $13,000 (equivalent to approximately 300 million VND), Tran Huong Lan and Nguyen Hoang Trung Dung – two sophomores of VinUniversity’s College of Engineering and Computer Science – have engineered a similarly effective full-feature sensor for a TOTAL COST of less than $750. This device can automatically sample wastewater based on pre-set time and volume for each sampling round.

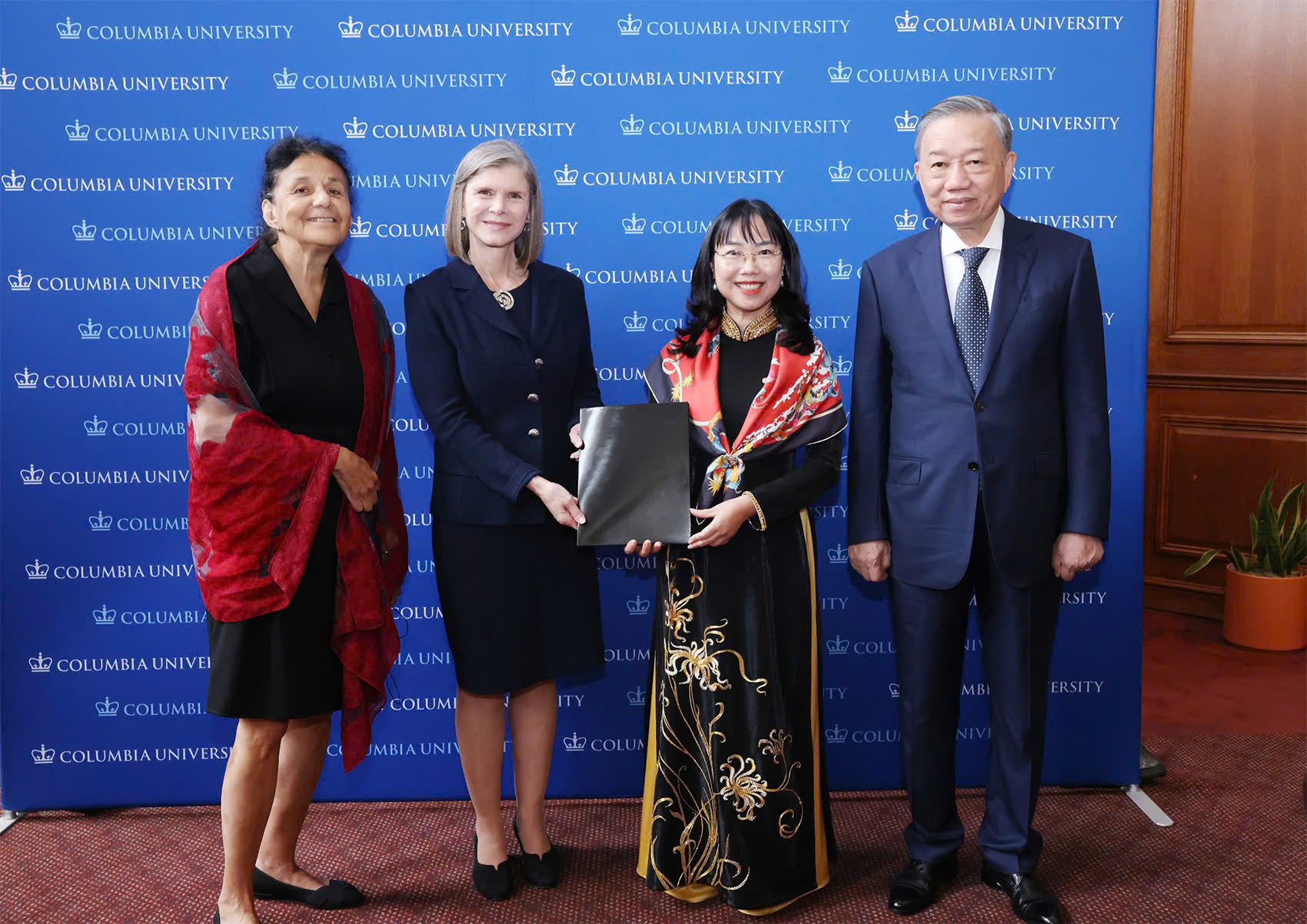

The research project is led by Prof. Thanh H. (Helen) Nguyen, Distinguished Lecturer in the Department of Civil and Environmental Engineering, Grainger School of Engineering, University of Illinois Urbana-Champaign (UIUC), with the participation of Professors, Lecturers and students from VinUni and UIUC.

To engineer this device, the students thoroughly studied the device’s technical requirements, including the automatic timer and the collected wastewater volume monitoring function, while utilizing their knowledge about hardware (driver, pump, drill, microprocessor, sensor) and software (product design, Arduino board, HTTP address, GG API, Wifi).

Lan and Dung revealed that in the engineering process, they received dedicated instruction and valuable learning opportunities from professors and experts in different fields:

“Prof. Helen Nguyen and Prof. Arthur R. Schmidt, who specialize in Environmental Engineering at UIUC, have helped us with the technical requirements, prototype preparation and sample design to turn biological requirements into engineering requirements. From VinUniversity, Prof. Do Danh Cuong, specializing in Electrical Engineering, supported the team in creating the actual product. In addition, the team also received support from Robert Schmidt, a UIUC student, during the installation of the device at the sampling sites.” – Lan shared.

The students added that despite directly visiting the wastewater sampling sites to observe and plan each stage of the device engineering to accelerate the sampling process, they still had to constantly monitor the device to ensure accurate operation and provide troubleshooting in time: “In fact, there are always errors and breakdowns arising in the device’s process of operation. Therefore, the flexibility and creativity in fixing the errors, replacing the components, and providing backup plans to ensure smooth operation is very important.” This is also one of the valuable lessons they learned upon experiencing the product engineering process with instant application into actual research.